Introduction

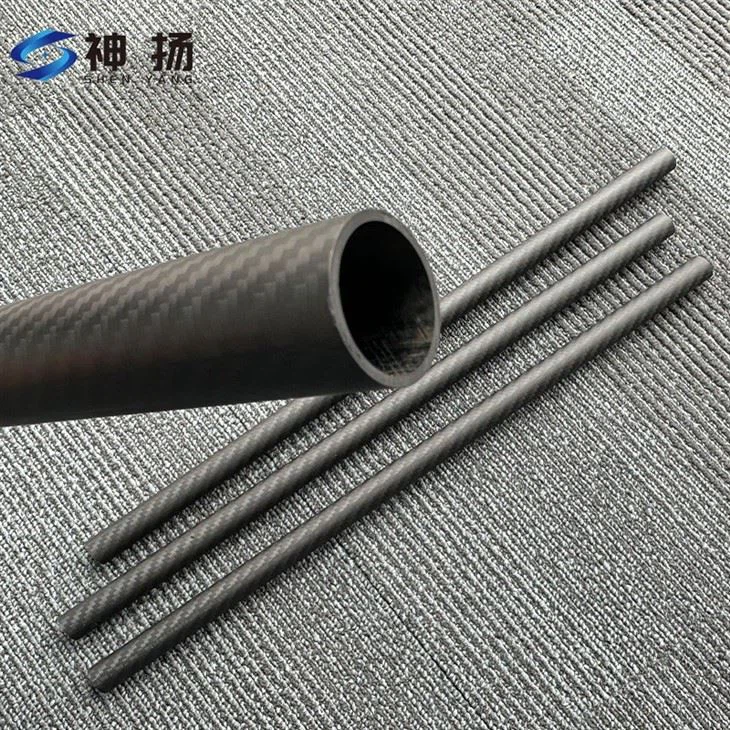

Matte carbon fiber tubes are manufactured using premium carbon fiber prepregs and feature a low-reflectivity, satin-finish surface. Through a specialized surface roughening process, these tubes eliminate glare while maintaining the lightweight and high-strength characteristics of carbon fiber. Matte carbon fiber tubes are primarily used in precision optical equipment, military hardware, and professional photography applications where minimal reflectivity is crucial.

Product Specifications

|

Specification Name |

Value |

Remarks |

|

Carbon Fiber Grade |

T300/T700/T800 carbon fiber prepreg |

Customizable |

|

Resin Matrix |

High-performance epoxy resin system |

120°C curing system |

|

Surface Reflectivity |

≤15% |

Professional anti-glare finish |

|

Fiber Content |

58±2% |

Optimized strength-to-weight ratio |

|

Molding Process |

Vacuum Assisted Resin Transfer Molding |

VARTM process |

|

Surface Roughness |

Ra 1.2–1.8μm |

Uniform satin texture |

Product Features & Applications

The standout feature of matte carbon fiber tubes is their understated, non-reflective surface-in sharp contrast to the glossy high-reflection finish of polished tubes. We utilize a proprietary surface treatment process to ensure reflectivity stays below 15%, effectively preventing glare under intense lighting. Unlike post-treatment sandblasting, our matte effect forms during curing through a micro-structured finish, delivering excellent durability.

• Military and tactical applications: Matte carbon fiber tubes are indispensable for military gear such as sniper rifle barrel shrouds and night vision mounts, where reflectivity can reveal positions. The matte finish blends seamlessly into the environment, eliminating detection risk. Glossy tubes, while premium in appearance, are unsuitable for such covert operations. Colored tubes are even more conspicuous.

• Photography and optical equipment: Photographers understand the importance of anti-glare gear. Tripods, light stands, and camera rigs made from matte carbon fiber eliminate unwanted light reflections, improving image quality. The matte finish is also fingerprint and smudge resistant-practical for frequently handled equipment.

• Precision instruments: Devices like rangefinders and spectrometers often require matte carbon fiber casings to reduce interference from ambient light. Matte finishes help prevent measurement errors caused by reflections-a must-have for high-accuracy systems.

• Medical equipment: Surgical tools and device stands used under intense lighting must avoid reflective surfaces that may distract medical staff. Matte carbon fiber tubes offer excellent optical comfort, are antibacterial, and easy to clean-outperforming traditional metal alternatives.

• Drone and model-making: Matte carbon fiber tubes prevent lens flare and ghosting in aerial photography, especially in sunlight. The subdued surface looks professional and fits commercial drone aesthetics. Competition-grade RC aircraft also prefer matte finishes for better visual tracking during flight.

Detailed Product Insights

Our matte carbon fiber tubes are manufactured using advanced techniques to ensure accurate fiber content and high surface quality. During the fiber layup stage, a 45° cross-ply configuration is used to enhance torsional stiffness and provide a consistent base for matte texture. Each ply is meticulously aligned to optimize mechanical properties.

The resin system plays a key role in the matte effect. Our specially formulated epoxy contains anti-glare and surface-modifying agents that migrate during curing to form a micro-rough surface texture. Curing is conducted at 120°C for approximately 2 hours, allowing full resin cross-linking without degrading the matting agents.

Unlike gloss finishes that require polishing, matte tubes need a more complex surface control process. Post-demolding, the surface roughness is adjusted with light sandblasting using ceramic microbeads (100–200 μm). Spray angle and pressure are carefully managed by experienced technicians to avoid over-roughening.

Quality assurance emphasizes reflectivity testing. Using gloss meters at multiple angles, we verify that all surfaces meet the ≤15% reflectivity standard. Microscopes examine the microstructure for uniformity, ensuring no bright or dark spots. Mechanical properties (tensile strength, flexural modulus, interlaminar shear) are tested on every batch.

Dimensional accuracy is equally important. Outer diameter tolerances are within ±0.1mm, inner diameter within ±0.1mm, and wall thickness deviation below ±5%. 3D coordinate measurement machines (CMMs) ensure full dimensional compliance.

Packaging is tailored to protect matte surfaces. Each tube is individually seated in custom EPE foam inserts to avoid impact damage. The outer carton features dual-layer corrugated cardboard with shock-absorbing fillers for safe transport.

Product Certification

As a specialist in dry carbon composite products, SYCarbonFiber has deep expertise in matte carbon tube production. We are ISO9001:2015 certified, with rigorous QC processes covering raw material procurement to final delivery. CE and ROHS certifications ensure EU market compliance and support environmentally responsible manufacturing.

Our facilities include gloss meters, roughness testers, universal testing machines, and more. These instruments ensure consistency in matte appearance and mechanical performance. We've served clients in defense, aerospace, and medical industries with tailored matte solutions, receiving excellent feedback on optical performance.

Comprehensive Service & After-Sales Support

We offer professional engineering support from drawing review to process optimization. Our technical team assists clients throughout production planning and provides real-time progress updates. Full quality inspections and detailed reports are provided before delivery.

We guarantee 12 months of quality assurance. Any product issues under normal use will be resolved via free repair or replacement. Our customer database ensures seamless future support and repeat order processing.

FAQs

Q: Does the matte surface treatment affect tube strength?

A: No. The matte finish forms during the curing process as part of the resin system. Surface texture depth is only tens of microns and has no significant impact on structural integrity. Test data confirms that matte and gloss tubes offer equivalent mechanical performance.

Q: Can you produce extra-long matte carbon fiber tubes?

A: Yes. Our equipment supports lengths up to 6 meters, with diameters from 8mm to 300mm. For longer lengths, we offer joining techniques with seamless matte surface continuity.

Q: Will matte tubes fade or change appearance outdoors?

A: No. Our matte treatment has excellent weather resistance. UV and salt spray testing show stable surface properties for 5–8 years of outdoor use.

Q: Can you customize matte tubes based on drawings?

A: Absolutely. We specialize in made-to-spec matte tubes. Just send your technical drawings with dimensions, tolerances, and layup requirements. Our engineers can help optimize the design as well.

Q: Are small-quantity orders expensive?

A: No. We support small-batch orders (even under 10 pcs) with competitive pricing. There's no MOQ. All trial production technical support is free of charge.

Products Description

SYCarbonFiber has recently upgraded its matte carbon fiber production line with new surface processing equipment, offering enhanced control over reflectivity and texture. We're also collaborating with research institutes to develop next-generation low-reflectivity composites, providing clients with more advanced options.

Hot Tags: matte carbon fiber tubes, China matte carbon fiber tubes manufacturers, suppliers, factory, carbon fiber tube, Molded Carbon Fiber Tube